Special Projects

In our experience as developers of technological solutions for the industry, we have worked on various projects that have delivered strategic value to our clients. Our capacity for innovation and adaptation allows us to offer unique and customized solutions that address the most demanding challenges. Below, we present some of our highlighted projects:

Virtual Commissioning

Virtual Commissioning is a methodology that enables the simulation and validation of industrial systems before their implementation on the plant floor. Through virtual environments, we replicate the operation of machines and processes, identifying potential issues and optimizing their performance prior to commissioning.

What it’s used for: It facilitates early error detection, reduces installation and commissioning times, and minimizes costs associated with failures during implementation.

What the development involves: It requires 3D modeling, integration with control systems, and the use of advanced simulation tools. The process includes close collaboration with the client’s design and engineering teams to ensure an accurate representation of the system.

Traceability

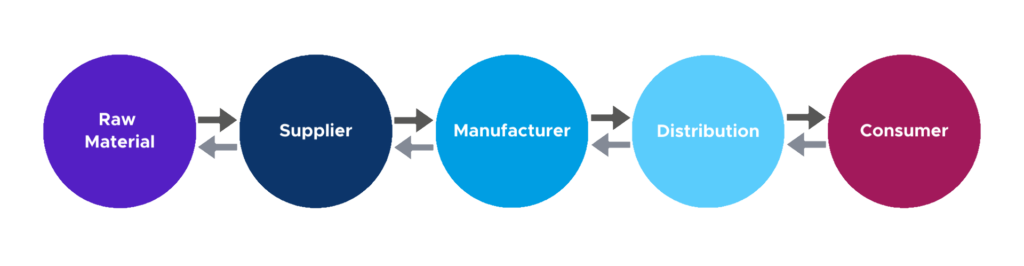

Industrial traceability is essential for ensuring the tracking and recording of products throughout the entire production chain. We design systems that capture data in real-time, providing a complete view of each product’s lifecycle.

What it’s used for: It ensures compliance with regulations, improves quality control, and increases customer confidence by enabling the tracking of a product’s history.

What the development involves: It includes the design of data capture systems, integration with hardware (such as QR codes, RFID), and the development of platforms for data storage and analysis.

Technologies we work with:

Non-Destructive Testing (NDT)

NDT systems enable the evaluation of material and component quality without compromising their integrity. We utilize technologies such as ultrasound, WMPI, MFL, and automated visual inspection techniques to ensure the highest quality standards.

We specialize in the integration of inspection systems and data processing to generate reports, perform advanced analytics, and develop artificial intelligence models. These models are specifically designed for the detection of unconventional defects, providing innovative, high-value solutions to optimize processes and enhance quality.

What it’s used for: Detects defects, prevents failures, and ensures the reliability of products and processes.

What the development involves: Requires the integration of advanced sensors, signal processing, and software development for data interpretation and storage.

Task Execution and Control System

This system provides a centralized solution that replaces the use of paper or Excel spreadsheets, offering a modern and efficient tool. It allows for highly flexible configuration of verification rules, adapting to customized criteria, logical rules, and comparisons. Additionally, it supports integration with other systems by enabling the automatic triggering of actions and sending messages based on the results obtained.

Among its key features, the system generates detailed statistics on the use and execution of verifications, providing valuable data for analysis and decision-making. It also includes tools for managing users with different access levels and creating workgroups to optimize collaboration and internal organization.

In summary, this system combines versatility, automation, and intelligence in a centralized environment, simplifying the management and tracking of tasks or processes. Our solution includes intuitive platforms that ensure compliance with routines and accurate data capture.

What it’s used for: Optimizes operational processes, improves inspection execution, and enhances data-driven decision-making.

What the development involves: Includes the design of mobile or web applications, integration with databases, and configuration of automated alerts.

Technologies we work with:

Production Management System

We implement customized systems that monitor and analyze key production indicators in real-time. These tools enable resource optimization and maximize operational efficiency.

What it’s used for: Provides full visibility into production processes, helps identify bottlenecks, and improves OEE (Overall Equipment Effectiveness).

What the development involves: Involves the integration of sensors, development of interactive dashboards, and algorithms for data analysis.

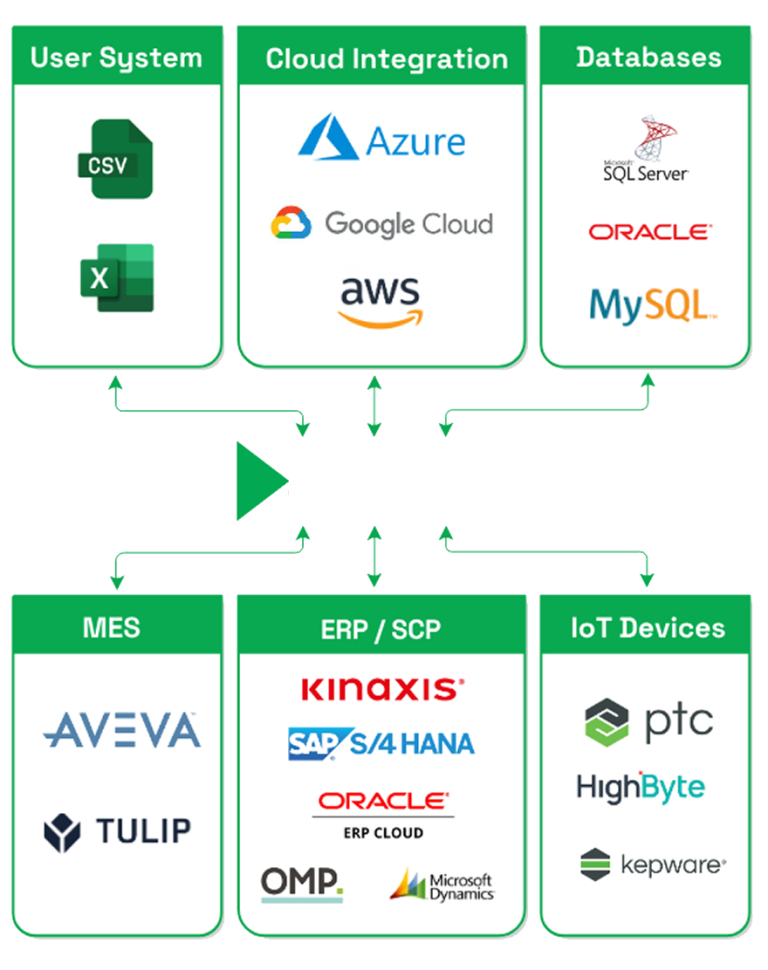

Technologies we work with:

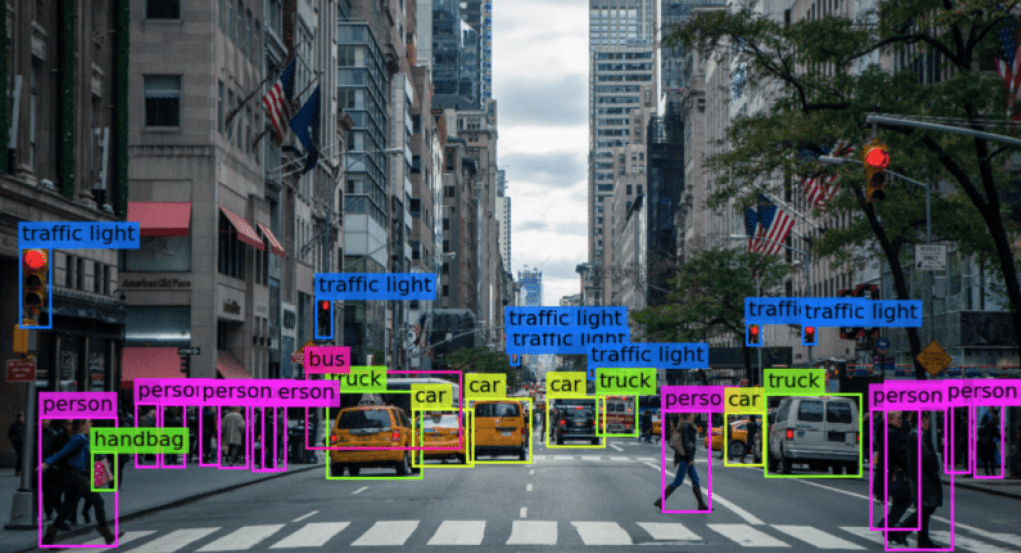

Object and Person Recognition

We design artificial intelligence-based systems for the detection and classification of objects and people in industrial environments. These solutions are key to enhancing safety and automation.

What it’s used for: Detects intruders, ensures compliance with safety regulations, and facilitates task automation.

Qué implica el desarrollo: Incluye entrenamiento de modelos de machine learning, desarrollo de aplicaciones para procesar imágenes en tiempo real y configuración de alertas automatizadas.

Technologies we work with:

Video Analytics / Image Processing

Our expertise in video analytics spans from quality inspection to industrial security. We use advanced algorithms to process and analyze images, generating valuable insights.

What it’s used for: Automates anomaly detection, optimizes inspection processes, and enhances industrial surveillance.

What the development involves: Requires the design and implementation of neural networks, optimization of real-time data processing, and deployment in industrial environments.

Technologies we work with: