CogniSight

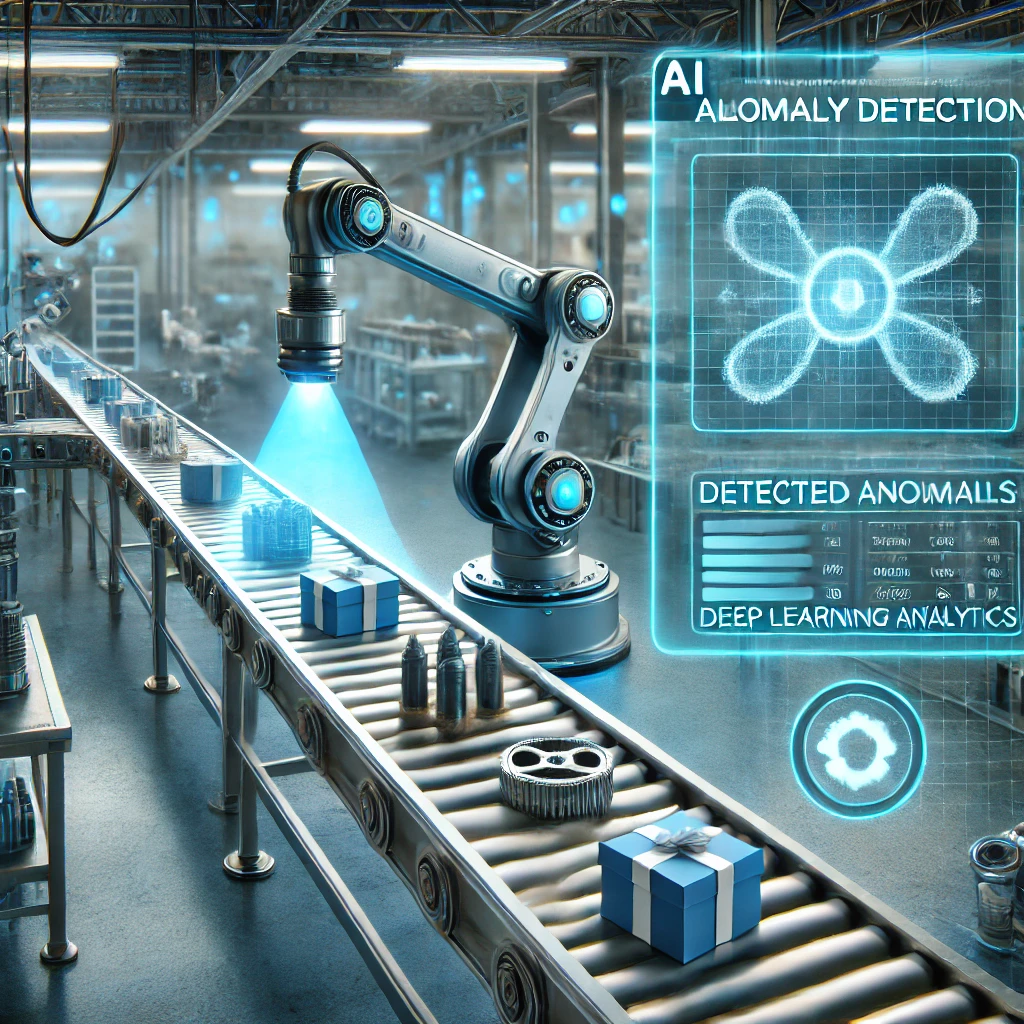

Kupner’s advanced solution for early anomaly detection in industrial processes. Leveraging filtering techniques, equalization, and deep learning, it accurately identifies irregularities, optimizing quality, reducing costs, and enhancing operational efficiency. With CogniSight, we take control and continuous improvement to the next level.

Transforming Data into Intelligent Decisions

CogniSight is an advanced solution developed by Kupner for the early detection of anomalies in any type of industrial process. It employs a combination of filtering techniques, equalization, and deep learning to identify irregularities in products or processes, improving quality, reducing maintenance costs, and optimizing operational efficiency. With CogniSight, we transform how industries approach control and continuous improvement.

Early detection of deviations

Early detection of deviations Centralized control and monitoring

Centralized control and monitoring Alarm and anomaly history

Alarm and anomaly history Variable management by assets

Variable management by assets